As a new generation begins to take over the workforce, the future of supply chain management will move towards utilizing the latest innovations to improve data reliability, faster workflows, synced data with interconnected systems and much more beyond our imagination.

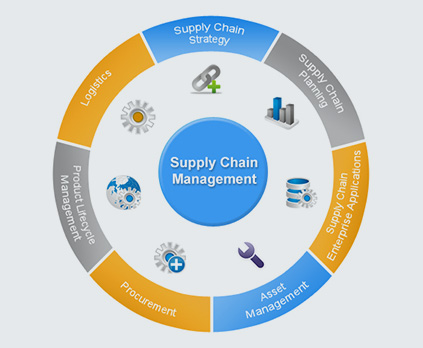

Image: Supply Chain Management Chart (Source: Maktree Solution)

What is Supply Chain Management?

Supply Chain Management (SCM) is the oversight of materials, information and finances as they move from manufacturing, importing/exporting, warehousing, distributing and eventually selling a product. This had traditionally been a fairly simple concept for centuries, but new technology in a global economy has made it very complex. Companies hire a lot of highly-skilled people to work in the supply chain for this reason.

What are the issues that are holding us back on improving the supply chain though?

Image: Telex Machine (Yes, this was pre-telefax)

The Fear of Implementing New Technology

Some companies that have been in business for decades have survived with changes in technology, but a bulk of those changes have been a step up from what was currently being used. What we are looking at are new concepts with completely new technology to improve efficiencies in the supply chain.

Forget about barcodes, RFID has existed for years now, greatly improving Wal-Mart’s logistics significantly. Pushing data to the cloud to populate on your data analyst’s computer to generate reports and review trends. Integrating all departments to a central system, where manufacturing/import, warehouse, accounting and sales are all linked back to the same data set. The fear comes in when you start to think, “what if something goes wrong?” or “I don’t understand it, so I don’t want to do it.”

With new solutions come new problems, and new problems come with new solutions to solve these problems. Find the right technology to implement, and have the right people to train your team to use these new tools effectively.

Sure, we could have gotten by with the telegraph if we wanted to stay comfortable with the current technology of that time, but we have come so far with improved ways of communicating. A fax machine was an improvement over the Telex machine. An email was an improvement over both conventional paper mail and the fax machine. There are still many companies that fear the use of email and cloud computing for sharing data and documents. Nothing wrong with the fear of getting hacked or losing digital documents, but don’t expect to stay ahead of the curve in today’s environment.

Image Source: Elite Business Magazine

Talent Gap

The biggest challenge companies are facing is finding a talent that understand both the the technology and the business to develop systems that match the requirements set by leadership, usable by the existing staff and actually have an intimate understanding of the supply chain.

It is essential to understand the flow of information, how it is generated, where it goes and how it eventually becomes a report for a certain department, or usable data to track trends and project for the future. User experience is a major factor in implementing an updated or new system. It must be simple or complex enough to get what you need from the respective departments.

Plan for Major Changes to the Supply Chain Today

Managers can review the way things are currently done, and take a closer look at how the current system can be improved. This could also identify technology gaps that existed before, but may be fixed with today’s widely available solutions.

In-house development used to be all the hype, but companies are quickly learning that solutions developed outside have become very detailed and cost effective. A great in-house IT team would be able to review these solutions, find ways to interconnect and integrate these solutions together. They would also know if this can’t be done due to software or system limitations, but may be able to work with the outside developer to customize how data is transferred between systems.

Plan to have systems from all departments link back to the same data sets. This could be done where each department keeps their own data, but pushes a copy out live, hourly or daily to a central database. Common mistakes could be found and prevented by setting requirements or limitations for users. There could also be parameters set up to give red flags when something appears to be an error and requires review. This could then protect the individual departmental information, and still have an integrated system in place for fast and accurate information to be passed along to the decision makers.

Plan for Success

Many organizations in the world of logistics and the supply chain are far behind when it comes down to technology and implementing innovative solutions. The good news is that it leaves a lot of room for growth and also stimulates competition as the industry evolves. We can only improve from where we stand today!

Interested in being part of our team?

Interested in partnering with us for your freight?